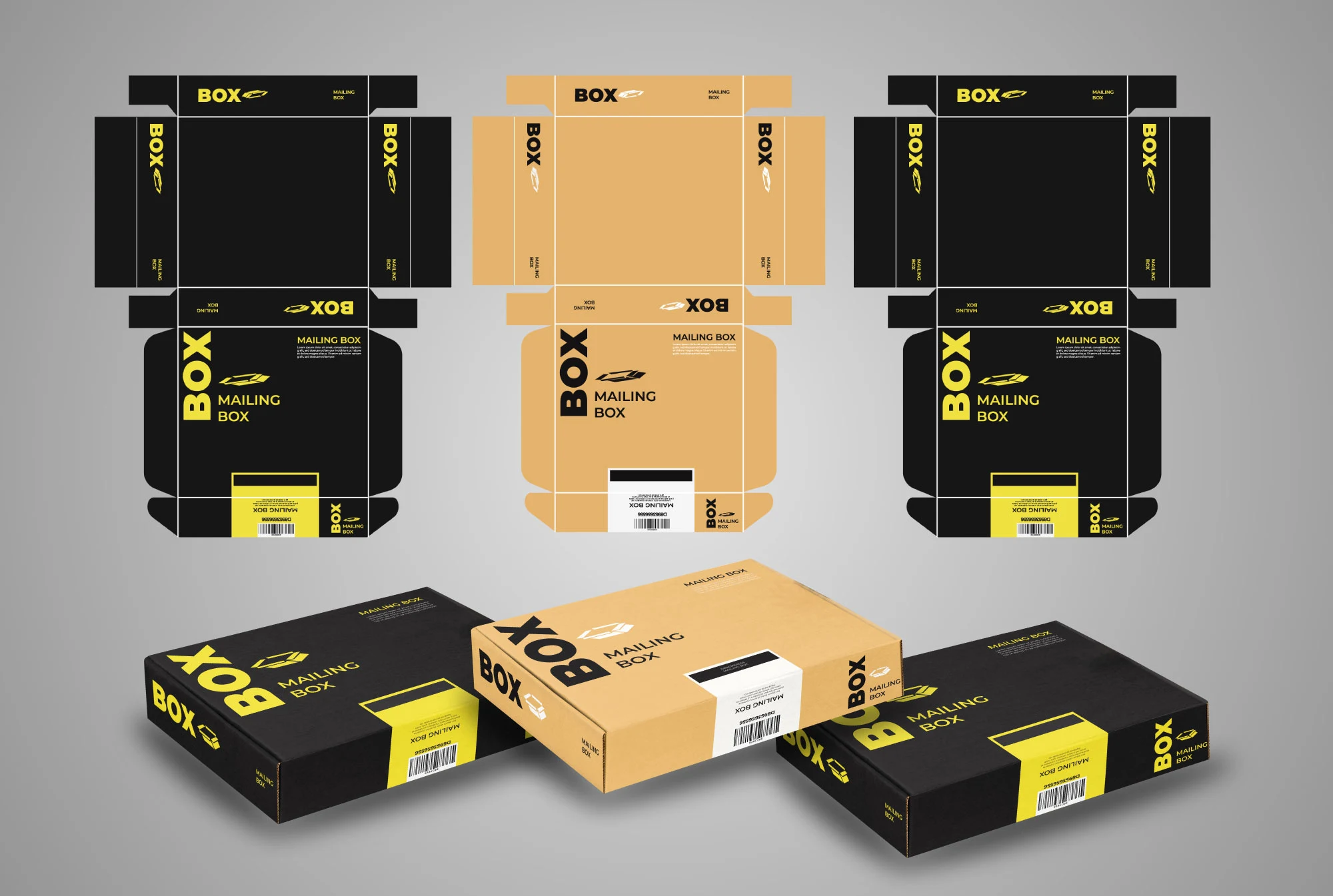

When it comes to creating professional and eye-catching packaging solutions, the die cutting process plays a crucial role. Whether you are designing custom packaging boxes, custom mailer boxes, or custom cardboard boxes, understanding the die cutting process is essential for achieving precise, high-quality results. Packwhole specializes in providing top-tier die cutting services that enhance your packaging designs and meet your specific needs. In this blog, we will explore the die cutting process in packaging, highlighting its importance, techniques, and benefits.

Understanding the Die Cutting Process in Packaging

The die cutting process is a manufacturing technique used to cut, shape, and emboss materials such as cardboard, corrugated fiberboard, and other packaging substrates. It involves creating a custom steel rule or rotary die that precisely cuts the material into desired shapes and designs. This process is vital for producing custom packaging boxes, custom mailer boxes, and custom cardboard boxes with intricate details and consistent quality. The die cutting process ensures that each package is uniform, professional, and tailored to the brand’s specifications, making it an indispensable part of modern packaging production.

The Role of Die Cutting in Creating Custom Packaging Boxes

Custom packaging boxes are designed to fit products perfectly while providing an attractive presentation. The die cutting process enables manufacturers to produce these boxes with intricate cut-outs, tabs, and unique shapes that align with the brand’s identity. By utilizing custom dies, companies like Packwhole can craft packaging solutions that stand out on shelves, improve product protection, and enhance the unboxing experience. Whether it’s a simple rectangular box or a complex folding carton, the die cutting process ensures precision and consistency in every piece.

Types of Die Cutting Techniques Used in Packaging

There are several die cutting techniques used in the packaging industry, each suited for different design requirements. The most common include flat bed die cutting, rotary die cutting, and kiss cutting. Flat bed die cutting is ideal for thicker materials and provides high accuracy for larger runs. Rotary die cutting offers faster production speeds for continuous operations, making it suitable for high-volume orders. Kiss cutting involves cutting through the top layer of material without cutting through the backing, perfect for individual labels or inserts. Packwhole employs these techniques to produce a wide range of custom cardboard boxes and custom mailer boxes tailored to clients’ needs.

Materials Suitable for the Die Cutting Process

The die cutting process is compatible with various materials, including corrugated cardboard, chipboard, paperboard, and other packaging substrates. These materials are selected based on the product’s weight, fragility, and branding requirements. For instance, custom corrugated boxes require sturdy materials to protect heavy items, while custom mailer boxes benefit from lightweight, durable materials that facilitate shipping. The choice of material impacts the die’s design and the overall quality of the finished product. Packwhole ensures the optimal selection of materials to match each project’s specifications, guaranteeing durability and visual appeal.

Designing for Die Cutting: Key Considerations

Designing packaging with die cutting in mind requires careful planning to ensure manufacturability and aesthetic appeal. Designers need to consider factors such as cut line placement, fold lines, and material thickness to avoid issues like tearing or misalignment. Including bleed areas, safe margins, and detailed dielines helps streamline the production process. At Packwhole, our experienced team collaborates with clients to develop designs that are both visually stunning and compatible with the die cutting process, resulting in high-quality custom packaging boxes and custom mailer boxes that meet all expectations.

The Benefits of Using the Die Cutting Process in Packaging Production

Implementing the die cutting process offers numerous advantages, including precision, repeatability, and versatility. It allows for intricate designs and complex shapes that would be impossible with traditional cutting methods. Consistency in every piece ensures a professional look, enhancing brand image. Additionally, die cutting reduces material waste, making it an environmentally friendly option. For businesses seeking to produce eye-catching packaging, the die cutting process is an efficient solution that delivers high-quality results and supports customization, especially for custom cardboard boxes and other packaging products.

Quality Control and Finishing in the Die Cutting Process

Quality control is a critical aspect of the die cutting process. Ensuring that each die is sharp, properly aligned, and maintained prevents issues like uneven cuts or tearing. Packwhole employs rigorous quality checks throughout production, including inspecting die cuts for accuracy and consistency. Finishing touches such as embossing, foil stamping, and matte or gloss lamination can be added after die cutting to enhance visual appeal and durability. These finishing techniques complement the die cutting process, resulting in premium custom packaging boxes that stand out in the marketplace.

How to Choose the Right Die Cutting Partner for Your Packaging Needs

Selecting a reliable die cutting partner is essential for achieving the best results for your packaging projects. Factors to consider include experience, equipment quality, turnaround times, and the ability to handle custom designs. Packwhole has extensive expertise in producing custom mailer boxes, custom corrugated boxes, and other packaging solutions with precise die cutting. A good partner will also offer design support and material recommendations to optimize your packaging’s functionality and aesthetics. Working with the right manufacturer ensures your packaging stands out and effectively protects your products.

Future Trends in the Die Cutting Process for Packaging

The die cutting industry continues to evolve with advancements in technology and materials. Digital die cutting, for example, offers greater flexibility for small runs and rapid prototyping, making it ideal for custom packaging boxes and mailer boxes. Additionally, sustainable materials and eco-friendly coatings are gaining popularity, aligning with environmentally conscious brand strategies. Automated die cutting machines with improved precision and speed are also enhancing production efficiency. Packwhole stays at the forefront of these trends, delivering innovative solutions that meet the changing demands of the packaging industry.

Conclusion: The Importance of the Die Cutting Process in Modern Packaging

In conclusion, the die cutting process is a cornerstone of modern packaging production. Its ability to create precise, customized shapes and designs makes it indispensable for brands looking to stand out with their packaging boxes, mailer boxes, and other cardboard solutions. With the right technique, materials, and partner like Packwhole, businesses can achieve high-quality, attractive, and functional packaging that elevates their brand image and improves customer experience. Understanding the die cutting process empowers companies to make informed decisions and leverage this technology for maximum impact in their packaging strategies.